The plastic industry’s fight against environmental degradation is akin to a modern-day battle of David versus Goliath, where the true enemy is not just pollution but the very materials that our society has come to rely on, challenging our future sustainability on a biblical scale.

Plastic pollution has emerged as one of the most pressing environmental challenges of our time, yet the issue is not singular but a complex web of problems tied to various types of polymers. From packaging materials to construction elements, plastics have become integral to modern life, and their synthetic nature poses significant disposal and degradation issues. The complexity arises from the diverse chemical structures of these materials. Each type of polymer is held together by unique chemical bonds, making the strategies for breaking them down not only varied but often incompatible.

Take polyethylene terephthalate (PET), commonly used in beverage bottles, and polystyrene, prevalent in food containers. Researchers have made strides in developing enzymes that can degrade these plastics, contributing to a burgeoning field of bioremediation aimed at mitigating plastic waste. However, these advancements are essentially partial solutions, addressing specific types of plastics but leaving many others, including polyurethanes, uncharted.

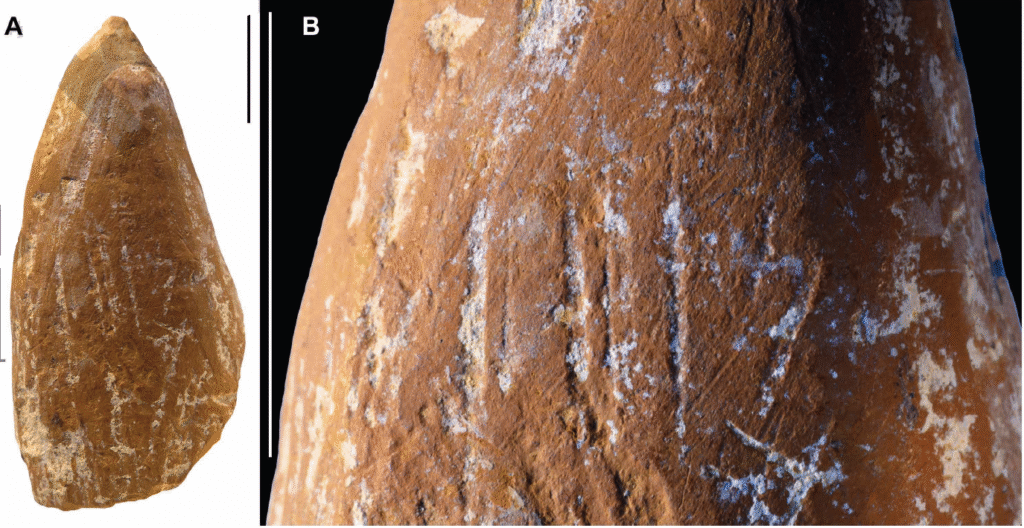

The introduction of a new enzyme capable of breaking down polyurethane signifies a pivotal moment in this fight. Polyurethane, a highly versatile polymer used in various applications—from foam cushioning to insulation—has long posed challenges for recycling due to its complex structure. The newly engineered enzyme represents a breakthrough in this arena, as it is designed to work within an industrial recycling framework that not only breaks down polyurethane into its basic components but does so efficiently. This capability allows for the possibility of producing new polyurethane from recycled materials, closing the loop in the lifecycle of this polymer.

The journey to develop such an enzyme showcases the growing sophistication of protein design tools available to researchers today. Techniques such as directed evolution and molecular modeling enable scientists to tailor enzymes with specific characteristics, enhancing their ability to function under industrial conditions where traditional methods may falter. This innovative approach could transform how we think about waste management in the context of plastics.

However, the complexity of plastic waste is not purely a scientific challenge. It intersects with social, economic, and political dimensions. The fast-paced consumption culture that epitomizes modern society is deeply intertwined with the life cycle of plastic products. The reliance on single-use plastics continues to shape consumer habits and perceptions, often overshadowing the urgent need for sustainable alternatives and effective recycling systems.

Moreover, the economic implications of recycling technologies cannot be overlooked. The establishment of efficient recycling processes requires significant investment and infrastructure, which can be a barrier for many regions. This economic disparity raises questions about equity in waste management practices, particularly in developing countries that grapple with the influx of plastic waste without the resources to address it effectively.

The ideological divide on how to tackle plastic pollution also reflects broader societal values. On one side are advocates for radical lifestyle changes and systemic shifts towards a circular economy, emphasizing the reduction of plastic usage and the promotion of biodegradable materials. On the other side are proponents of technological solutions, advocating for innovations like enzyme-based recycling and advanced waste management techniques. This divide can lead to heated debates, as each side presents compelling arguments about the best path forward in addressing a crisis that affects all facets of life on Earth.

As researchers continue to explore the potential of engineered enzymes, the implications of these findings extend beyond environmental benefits. They challenge us to reconsider our relationship with materials, waste, and consumption. The ability to recycle polyurethane on an industrial scale could serve as a model for addressing other challenging plastics, pushing the boundaries of current recycling methods. However, it also highlights the urgent need for comprehensive policies that incentivize sustainable practices across industries.

At the heart of this discussion is the question of responsibility. Who bears the burden of addressing plastic pollution? Is it the manufacturers who produce these materials, the consumers who use them, or the governments that regulate their use? This multifaceted dilemma requires a collective response, necessitating collaboration among scientists, policymakers, businesses, and the public. Only through concerted efforts can we hope to devise effective strategies that encompass both innovative technologies and profound social changes.

The emergence of enzymes capable of breaking down even the most stubborn polymers offers a glimpse of hope, yet it also serves as a stark reminder of the ongoing battle against plastic waste. This innovative solution must be coupled with a commitment to systemic change that addresses the root causes of plastic pollution rather than merely treating its symptoms. As we stand at this crossroads, the decisions we make today will shape the environmental landscape for generations to come.

You’ll often hear plastic pollution referred to as a problem. But the reality is that it’s multiple problems. Depending on the properties we need, we form plastics out of different polymers, each of which is held together by a distinct type of chemical bond. So the method we use to break down one type of polymer may be incompatible with the chemistry of another.

That problem is why, even though we’ve had success finding enzymes that break down common plastics like polyesters and PET, they’re only partial solutions to plastic waste. However, researchers aren’t sitting back and basking in the triumph of partial solutions, and they’ve now got very sophisticated protein design tools to help them out.

That’s the story behind a completely new enzyme that researchers developed to break down polyurethane, the polymer commonly used to make foam cushioning, among other things. The new enzyme is compatible with an industrial-style recycling process that breaks the polymer down into its basic building blocks, which can be used to form fresh polyurethane.